Recorded What's New Presentation

http://www.daxeam.com/Pages/daxeam-2012-version2-0-6-whats-new.aspx1 Support for Dynamics AX R2 CU7

Daxeam is now fully compatible with Dynamics AX R2 CU7.2 Install/Remove of non-serial positions

The exchange of non-serial positions will allow the installation records to be created without requiring that an asset record be created and this record will also allow maintenance planners to know meters in position for positions in the asset structure which do not have a tracked asset installed. Hence able to track the component and history of installed parts for forecasting and reporting purposes.

Key Features:

- Flexibility on exchange of a non-serial position and able to tell the system how many meters a non-serial component has been installed.

- On install to be able to specify the starting meter value and forecasting should work on the meter of the structure position

- Parts are aged when the asset has been aged based on the aging setup.

- Forecasting should work on the meter of the structure position.

- Add the install history to the inquiry. To be able to search and filter on component history.

3 Forecast costs added to reports/cube

The ability to see the projected costs of proposed work orders has been added to both the budget/actual report and Daxeam Cube. An option has been added to the forecast plan to calculate costs. When selected and a forecast plan is selected on the budget/actual report, then projected costs will be shown. The forecast plan has been added as a dimension to the cube in order to compare different forecast scenarios.Key Features:

- Ability to forecast maintenance costs.

- Knowing future cost allows for better scheduling.

- Ability to analyze forecast costs in the cube.

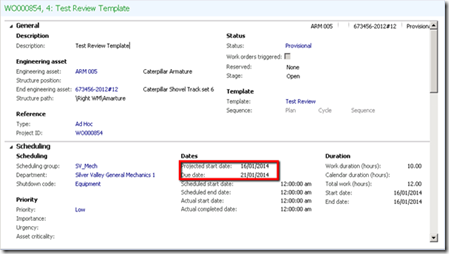

4 Work order due date

The “Due date” field is to facilitate work order line priority calculation. This date should be used to reflect the date in which the work must be completed. The due date could be expressed in terms of the projected date + any acceptable variance.

Key Features:

- A maintenance planner is able to specify the last day a work order may be executed.

- The system is able to calculate a “Due date” based on the template applied.

- The “Due date” can be calculated based on configuration in Condition based monitoring.

5 Scheduled Resources in Schedule Export

A new feature has been added to the scheduling tools which contains associated items/hours quantities and costs for all work orders in the schedule. Use this export to review all of the required resources and quantities required to perform work in the schedule. Create custom filters and then export to Microsoft Excel.

Key Features:

- View all resources required to execute work in a schedule

- This will generate an Excel file containing forecast items and hours.

6 Warranty Expiry Report

A new warranty expiry report has been added which will return all equipment where the warranty is due to expire within a specified date range. This report will work both with calendar based and meter based warranty periods.

Key Features:

- Ability to specify the time frame in which to check for estimated expiry.

- Ability to report by Equipment type, Specific Assets or Warranty contract.

- Shows expected expiry dates and whether the date is calendar or meter based.

7 Work Order Filter Groups

Functionality has been introduced to allow for the grouping of work order lines into “Filter Groups,” This functionality allows users to group work order lines on the fly or select an existing group to retrieve previously grouped work order lines. Additional work order lines can be added or existing work order lines can be removed with ease.Filter groups can be used to group work orders for shutdowns, inspection routes, and other scenarios where related work orders are to be executed as a group.

The filter group field has been added to the scheduling board and the scheduling details so that grouped work orders are easily identified in the scheduling tools.

A fact box has been provided to provide information pertaining to a selected scheduling group.

Key Features:

- Ability to create ad-hoc groups based on standard AX filters.

- Functionality to add or remove work order lines to existing filter groups.

- Visibility of filter groups on scheduling tools.

8 Inventory transactions install and remove.

Functionality has been introduced to, automatically, create inventory transactions during the asset install and remove procedure.An, optional, parameter has been created to allow for the system to create and post a project item journal during the asset install / remove procedure.

The system allows for the selection of an existing inventory item or defaults an associated inventory record from the asset type configuration. Inventory dimensions can be defaulted from the end asset record but can be reviewed and changed during the asset installation or removal. Financial dimensions are retrieved from the initiating work order line.

Key Features:

- Ability to automatically post inventory transactions to support asset install/remove.

- Ability to review asset/inventory origin via history

- Ability to crate inventory transactions for both the installation and removal using the exchange feature.

9 Control costs per job for work order hour forecast and registrations.

In this release it is now possible to specify a cost for job related transactions through the project category mechanism. A new button has been included in the work order type form to allow for project categories to be assigned to a job record for the selected work order type.

Key Features:

- Ability to specify specific costs and cost accounts for specified jobs and work order types.

- Increased forecasted cost accuracy

10 Show work orders on the net requirement Form

The net requirement form has been enhanced to include the work order reference if applicable. This provides increased visibility and usability by allowing the user to see at a glance if the net requirement is related to a work order and if so provides the ability to navigate directly to the work order line record.

Key Features:

- Ability to identify net requirement work order line association.

- Ability to navigate to the work order line from net requirement record.

11 Import attributes with engineering asset

The engineering asset import journal now allows for a maintenance data administrator or maintenance planner to perform a mass upload of engineering assets together with attached engineering asset attributes using a journal style interface. The journal post will initiate the creation of the engineering asset and the associated attribute values.The journal supports manually creating new journal entries and importing journal lines from a comma separated or text file.

Key Features:

- Create an engineering asset with attached attribute value during implementation using an import file.

- Allows for manual entry and import.

- Initializes imported engineering asset with default attribute values.

- Validates all mandatory attributes have been specified for the engineering asset.

- Validates attribute values for list type as well as bounded attributes.

12 Search by engineering asset attribute

Engineering asset attributes can now be added to the Engineering asset list page. A total of 5 attributes can be added to the list page and the attributes can be added or removed as per the user’s choice. The user can choose these attributes from the “Attribute” menu item on the related information button group which shows the entire attribute which are available to the Enterprise Asset Management module.Once added to the list page the engineering asset attributes can be used for sorting or filtering records.

Key Features:

- Ability to add attributes to the engineering asset list page.

- Ability for the users to choose which attributes to view on the list page.

- Ability to sort and filter engineering asset records by attributes on the list page.

13 Asset Hierarchy Added to Analysis Cube

The asset hierarchy can now be used to create reports from the EAM analysis cube. Use the hierarchy to create reporting by site, area, location, type of equipment, or department. Use the hierarchy for filtering existing reports or to see rolled up costs.

Key Features:

- Ability to report budget, actual costs, hours, PM forecast costs using the asset hierarchy

- Use the hierarchy for filtering results

- Create real-time pivot tables directly from your favorite analysis tool including Microsoft Excel.